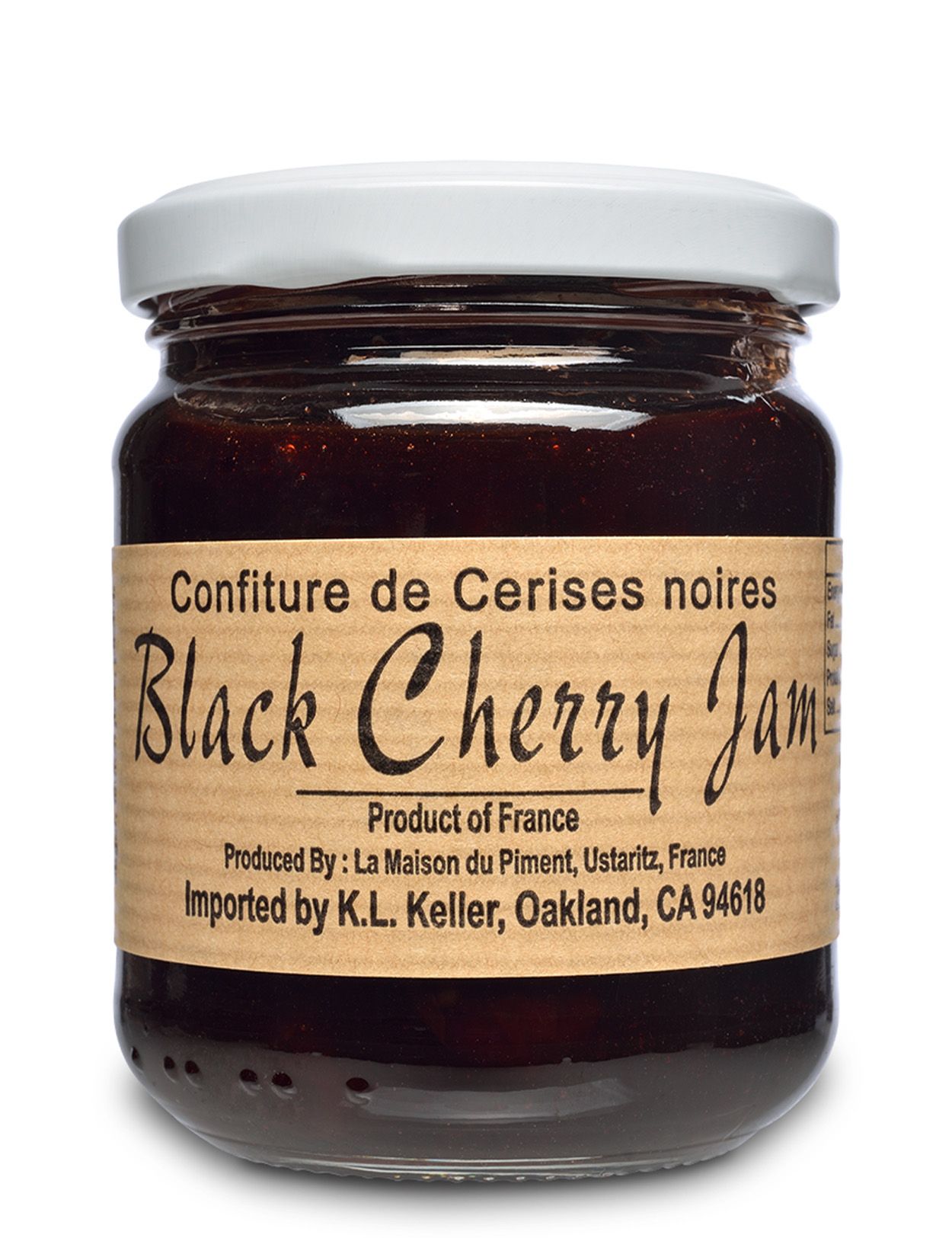

La Maison du Piment

-

Email:

This email address is being protected from spambots. You need JavaScript enabled to view it. -

Website:

-

Region:

-

Address:600 Rue du Bourg, Ustaritz, Nouvelle-Aquitaine, France, 64480

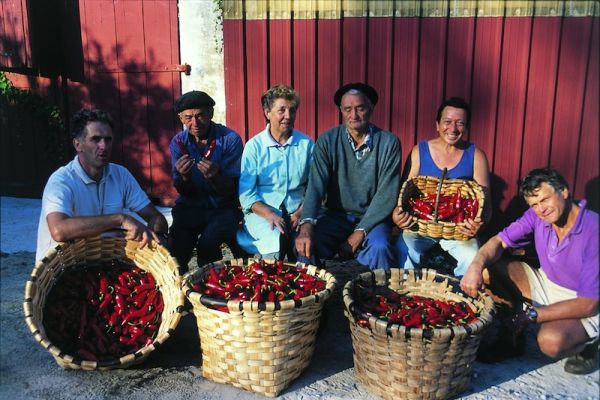

Piment d’Espelette AOP is a powder made from a particular spicy red pepper specific to the Basque region of France—grown from seeds that originally arrived during the time of Columbus. In the region, it served as a substitute for both salt and pepper. In 1994, Vincent Darritchon, founder of La Maison du Piment, started to commercialize his mother Marie Jeanne’s pepper plot. He and a handful of small producers set about trying to protect Piment d’Espelette from counterfeit products by pursuing the provenance and quality designation AOP. In 1997 they succeeded, and in 2001 it became official. Vincent and his wife Edith still have a home and office on their familial property.

La Maison du Piment cultivates a total of five hectares containing 96,000 plants—certainly a different scale than his mother’s—and yet everything is much the same as in Marie-Jeanne’s era. Since the AOP prevents mechanization, the amount of handwork necessary to produce Piment d’Espelette is quite awe-inspiring.

Here is the process: In early March, seeds are densely sprouted in the open-air greenhouses in a light potting medium. When they are about two to three inches tall, they are teased apart and placed individually into a plug of soil where they will grow in the green house until they are about ten inches high. In late April, the seedlings are planted and the mature plant eventually attains a height of about three to four feet. During the harvest from mid-August to the beginning of December, each field is passed over by hand every ten days.

The harvested peppers are sorted, with the very best going onto ropes to be cured and dried in open air. The others are ripened on wooden racks in open-air greenhouses for at least 15 days (per the AOP), then a team re-sorts for defects and the stem is removed by hand. The remaining peppers are placed on the racks again, and put in a kiln to dry slowly at a temperature of 104°-110° for one or two days as they turn from crimson to a deep maroon (interestingly, the bright orange-yellow filaments running through the pepper contain the spicy capsaicin). Finally, the peppers are ground to a prescribed mesh size and jarred or used to enhance other products.